In product design, it’s not enough that your new product is looking good. And if you want to lower product design costs, it has to be cost-effective to produce as well. You want to impress customers and make them to buy it. But overall cost also matters for business side. After all, price is a major factor in consumer’s buying decisions. This is why the overall cost to make a product is a major consideration for many designers.

Table of Contents

REDUCE PRODUCT DESIGN COST: But HOW

With some innovative thinking and creative execution, product designers can successfully come up with ideas to Lower Product Design Costs in a fairly manner.

For instance, some product designers and developers in New Zealand use a variety of techniques to lower the cost of a product. In fact, if you’re in Auckland, you can search for firms specializing in product design Auckland companies can rely on. Because they know best tricks for optimising product design costs.

Consider the following tips for the next time you’re redesigning your product:

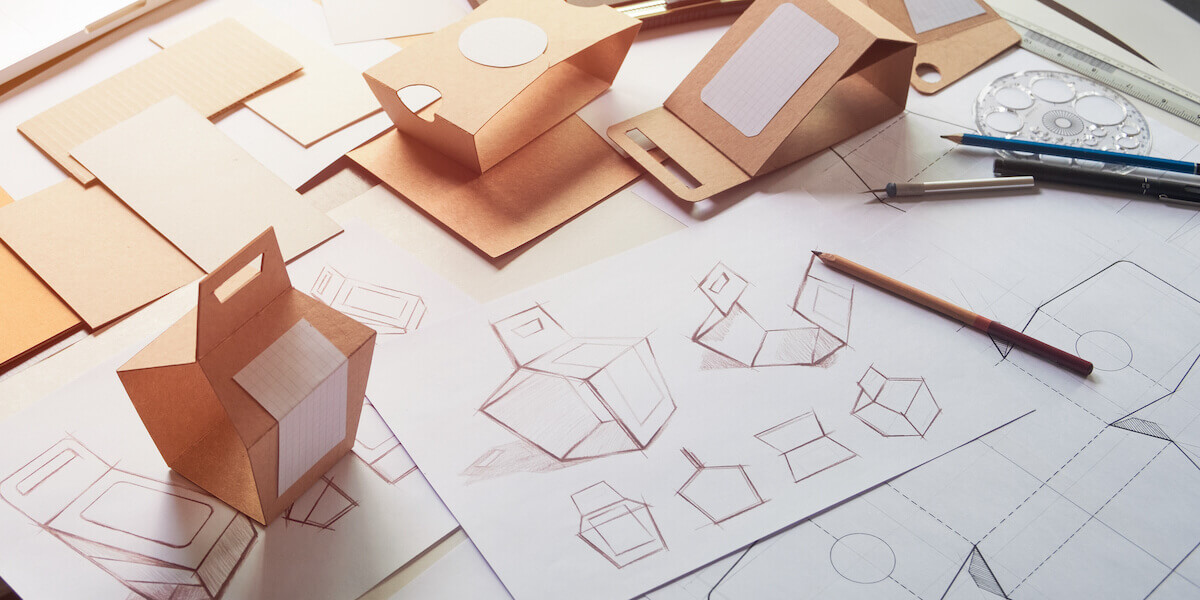

1. Simplify and Streamline the Design to Lower Product Design Costs

Simple design is actually not that simple it requires effort and creativity. But it is possible to reduce production costs and time by simplifying design principles.

Too complex and tiring designs also require different materials. Different materials means different vendors, different processing time. And they even affect the efficiency of production line.

A great example of this is the iPod Nano. It was first came out in the mid-2000s. As a downsize version of the Apple iPod, but it was priced significantly lower. Yet, the simple and small design enabled people to carry their music station along with them. Before that, maybe it was unimaginable to fit all songs in such a small design.

2. Select More Efficient Materials

The choice of materials can significantly impact the cost.

Materials matter for cost, performance and the new hype- sustainability. People care for material quality, and how these are machined. Are these material sustainable or fast production for example in textile?

Cost saving via recycled material or going simple for design can really reduce your material cost. In this way, you can focus more on efficient production. The more you have space for budget, you can also focus on customer experience and UI.

Reduce Costs in Product Design

A good case study of this principle is seen in various smartphone products. Smartphone manufacturers often use a variety of materials to offer a wide range of smartphones at different prices. For instance, their flagship model might be encased in higher price aluminium or glass but the phone models with lower price tags use plastic.

3. Optimize the Production

Efficient production processes are essential for minimising costs and maximising profitability.

Gotta minimize those costs and maximize the profits, right? Designers, they can optimize that production by going all in on automation, lean manufacturing, and constant improvement. These methods, they help eliminate waste, streamline the workflows. So designers can get that cost down without messing up the quality or reliability.

Minimize Product Development Costs in Productıon

Now, you know who pioneered that lean manufacturing stuff? Toyota, back in the 50s. Those Japanese car giants, they came up with this whole system based on their hardcore work ethic. It’s got the 5Ss – Sort, Set in Order, Shine, Standardize, and Sustain. This motto really helps cut down material waste like crazy in the factory. And these days, it’s not just for manufacturing, people are using these lean principles all over the workplace.

4. Ensure Accurate Product Cost Analysis: Optimising Product Design

Product cost analysis in product design and development involves evaluating the various costs associated with bringing a product to market, including material costs, labor costs, manufacturing expenses, and overheads.

It aims to identify areas where costs can be reduced or optimized without compromising product quality or functionality. By conducting thorough cost analyses throughout the design and development process, businesses can make informed decisions on how to maximize profitability and competitiveness in the market.

How can design costs be reduced?

Alright, so when it comes to getting that product cost analysis on lock, designers gotta be working closely with all kinds of teams – procurement specialists, manufacturing engineers, financial analysts, the whole nine. Gotta gather up all that data on materials, manufacturing processes, overhead costs, the works. And they can use some fancy cost estimation software too, plus regular check-ins during the design process to make sure those cost projections are tight.

You know IKEA? They’re the kings of this cost analysis game. That Swedish furniture giant, they’re all about affordable yet stylish stuff, right? But how do they do it? They analyze every single aspect of their products. These include design, manufacturing, distribution and it goes.

5. Factor In the Ease of Production

Those design choices, they got a big ol’ impact on the manufacturing complexity, the tooling costs, and even the assembly time. So designers, they gotta really think about that production ease to Reduce Product Development Cost. Gotta minimize all those headaches and extra costs. If they design with that manufacturability in mind, they can simplify the assembly, cut down on production errors, and straight-up lower those design costs.

Now, LEGO bricks? Perfect example of a product where the designer had that production ease on lock. Those bricks, they got a dead-simple yet genius design that makes assembly. So anyone can just build away without a hassle.

Understanding Reduce Product Development Cost

Alright, let’s talk LEGO manufacturing. From what we know, their whole injection molding process is quite efficient and cost-effective. The molds they use to make those little bricks are designed for, like, top-notch repeatability and durability. Means they can pump out tons of ’em with hardly any quality issues.

And you know, that cost-effective design is key for any successful product launch. If you can lower those manufacturing costs, you’re golden. Because it means in real life, higher profit margins and easy scaling up whenever you need to. So when you’re redesigning your product, just remember to keep an eye on that cost-effectiveness.

With more than 20 years of progressive experience as Program Manager and Project Manager had led complex IT projects/programs in a wide variety of industries in America, Latin America & Italia.

Mario Bisson Andini is an advanced Program Manager who is the founder of Bisson Training.