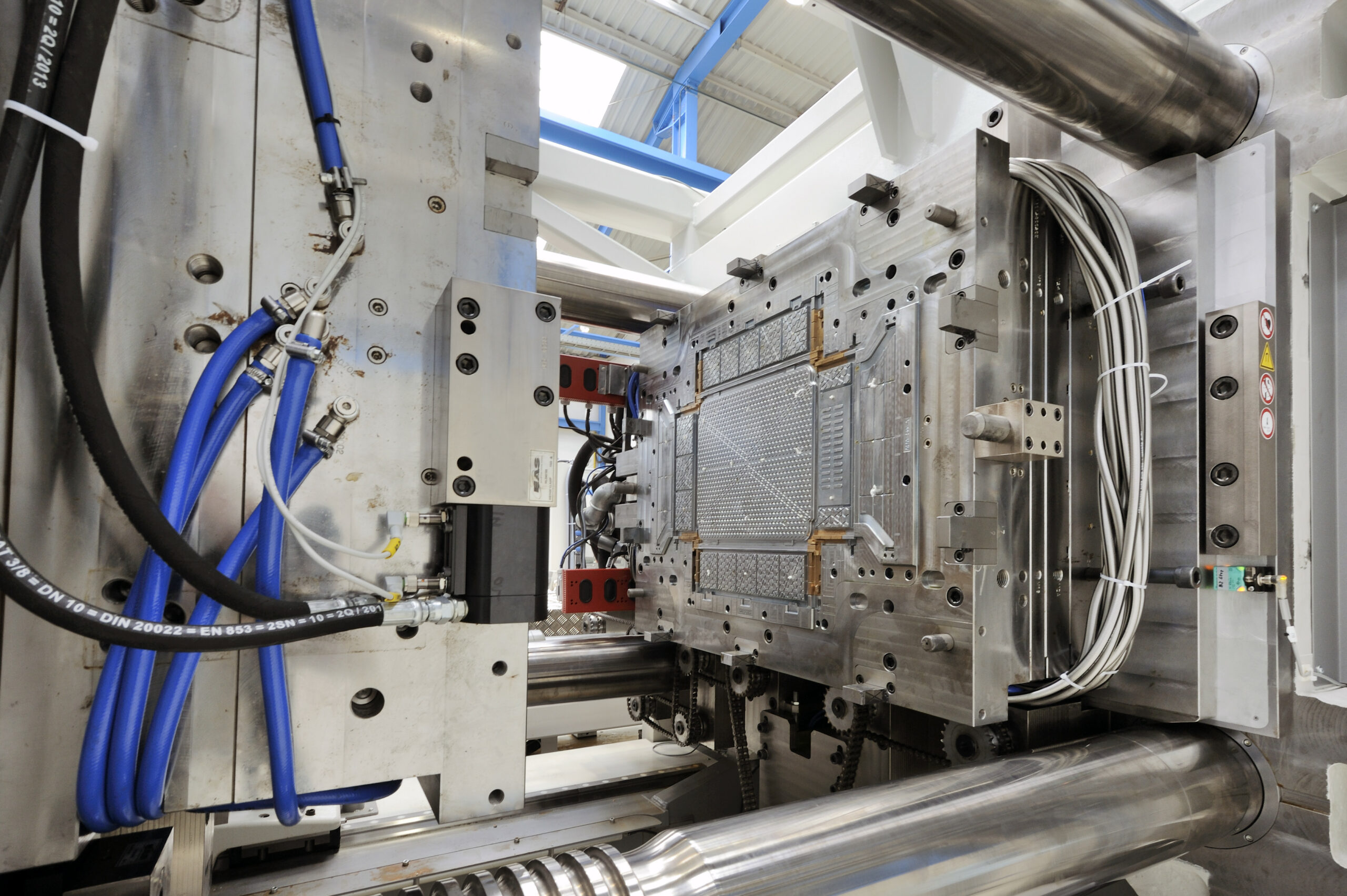

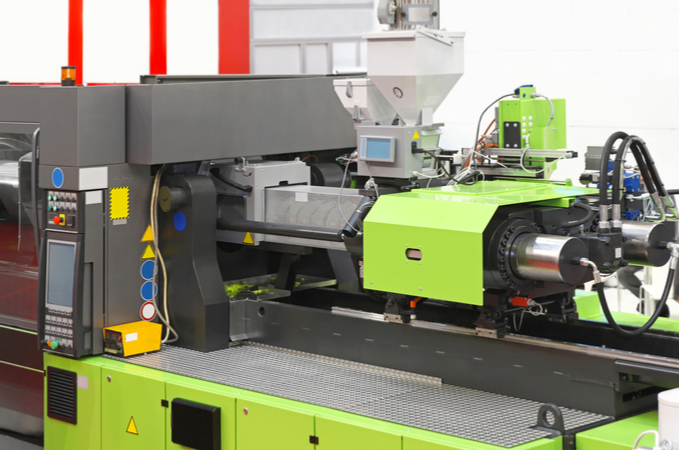

When it comes to producing plastic objects efficiently, the right technology can make all the difference. In places like Florida, where industries demand high precision and quality, a reliable plastic injection molding service is crucial. This service allows manufacturers to conveniently create complex shapes with high functionality by injecting molten plastic into a custom-designed mold. The process is not only easier but also ensures that each product meets exact specifications without compromising on quality. By using this method, companies can focus on delivering products that work as intended and are readily used across various applications. Whether you’re looking to produce small components or large-scale items, the flexibility and precision of this service make production smoother and more efficient.

In recent years, there has been a significant rise in the demand for plastic products across various industries. This technology has seen quite a few changes over the years and is now widely used in manufacturing services for fields like aerospace, construction, medical, plumbing, and many others. From creating intricate components for medical devices to producing sturdy parts for construction, plastic injection molding has proved its worth by delivering high-quality results efficiently.

This method not only excels in large-scale manufacturing but has also been highly effective in considerably smaller applications. Whether it’s making a small gear for a medical device or a complex component for an aircraft, this process ensures precision and reliability. Thanks to its versatility, companies can produce a wide range of plastic products with consistent quality, meeting the growing needs of various industries.

When aiming for superior quality in plastic parts production, having the right equipment and skilled personnel is imperative. The entire process, from designing to constructing plastic molds, requires a deep understanding of the mechanisms involved. In places like Florida, where industries demand precision, the best injection molding companies focus on delivering high-quality molds. The first and foremost thing these companies need to do is ensure they listen to their clients’ needs carefully. Before creating any plastic objects, it’s crucial to understand what is plastic mold in terms of material and design.

Using the best way possible, these companies ensure that all standards are followed meticulously. This method guarantees that the final products meet the required quality, making them reliable and durable for their intended applications. Choosing a company that is ready to listen and make clients feel heard is essential because there’s no point in working with a partner who doesn’t prioritize your needs. So, before anything, make sure they have asked about your specific requirements and are prepared to deliver according to those standards.

In the industrial sector, creating high-quality molds is crucial because they are the primary tools used to shape various units of plastic products. While secondary units might be used to improve the functionality and extend the life of these products, the role of the primary mold remains vital. It’s important to note that just because these secondary parts play a useful role in production, it doesn’t imply that the initial mold’s importance should be overlooked. In terms of production, every unit involved must perform efficiently to ensure the overall process runs smoothly.

When choosing a plastic injection molding service, you should work with a company that has a team of professionals who not only review the design internally but also sit with the customer to make sure that their needs are met. The decision of finalizing the layouts and designs should always remain in the hands of the customer. This collaborative approach ensures that the final product aligns perfectly with the client’s expectations, enhancing both production efficiency and customer satisfaction.

When selecting a company for your plastic injection molding needs, it’s wise to hire one that provides Moldflow analysis service. If a company does offer this, they are able to find defects in the molds at an early stage, which in turn will save you from spending extra money on mold testing and modification. This helps in optimizing the entire plastic injection molding process, making it very beneficial for identifying issues like deformation or shrinkage. It can also reduce process time significantly, ensuring efficient and cost-effective production.

Depending on your specific requirements, the right injection molding company can help streamline production by reducing the time needed to manufacture many units. When your production process is optimized, each unit can be made in lesser time, allowing you to meet demand more efficiently and maintain high quality. Additionally, exploring modern techniques like additive manufacturing can further enhance production capabilities, offering innovative solutions for creating complex plastic parts.

With more than 20 years of progressive experience as Program Manager and Project Manager had led complex IT projects/programs in a wide variety of industries in America, Latin America & Italia.

Mario Bisson Andini is an advanced Program Manager who is the founder of Bisson Training.